News

Quality of CADD Work

An Overlooked Key to Success?

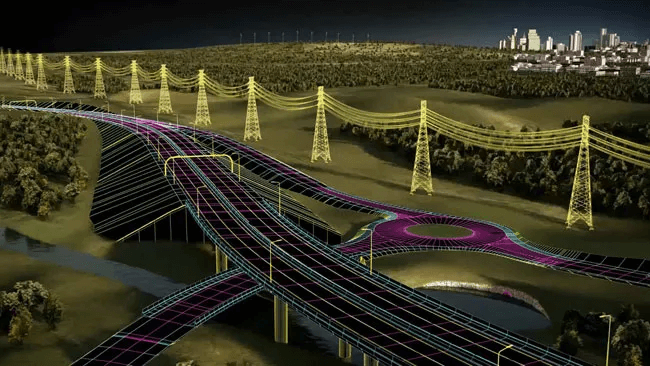

Computer-Aided Drafting & Design has been integral to the continued development of Civil Engineering and Construction for nearly four decades. Even though there are numerous software programs that contribute to the creation, modification, and optimization of design through computer-assisted means, the primary ones we think of today are programs that help design roads, bridges, and structures, or calculate earthwork quantities or analyze the flow of water. From the simplest set of lines and arcs in a two-dimensional plane, to the more complex simulations of surfaces, pipe networks, and structural analysis in three-dimensional space, we cannot understate the importance of CADD in our pursuit of better engineering and design. However, understanding the impact that quality CADD has on our industry goes beyond good practices within the individual software, but extends to how we produce quality in data management in our connected world.

Within any chosen CADD software, it’s imperative to follow a certain set of standards and good practices. No different than coding software or scheduling programs, there are always indicators of higher quality; using comments or notes to document thoughts or ideas, organizing data into an appropriate number of categories that follow a logical template or standard, and keeping backup copies and logs of critical changes made, are all examples of how we measure the quality of a product. Moreso, the ability to provide a certain level of transparency, ease of use for non-technical users, and providing paper-trail documentation, lowers the barrier for understanding the end-product as well as the process for how it was made. A good example of maintaining organized data and following standards within AutoCAD/Civil 3D or MicroStation would be naming conventions for layers/levels. Within these software, visual objects are assigned a layer/level that can control properties like colors, printing styles, and line styles. This allows for easier access and control of objects into groups or categories to more easily process large amounts of data. However, within a single file, if you have hundreds or thousands of layers/levels, it can become overwhelming or undermine the intent of having layers/levels in the first place. You can also bring in other “reference” files, which bring the layers/levels from their file into the file you’re working in, further increasing the number of layers/levels into the thousands or tens of thousands. This shows the importance of understanding how a tool/process works, but also understanding the weaknesses or shortcomings of a tool that is used improperly. In this scenario, having the ability to categorize and organize data is extremely useful, but if it begins to require another tool/process to organize that subset, it becomes less helpful.

As the world continues to grow more connected, in both a digitalized social/communal way and a technological software/data way, the necessity for technology to interact well with humans and other technology is crucial. As previously mentioned, the goal of producing a quality product (through CADD-assisted means) requires understandability by all parties and compatibility with a large range of other software and programs. Twenty or thirty years ago, the implementation of email and digital documentation was new and infrequently used, however it is both commonly practiced and understood within every industry today. In the same fashion, we should continue to not only use CADD software for the betterment of our industry, but we must also understand both how it functions and how it interacts with other facets of the design process. Looking forward towards new technologies such as Artificial Intelligence (AI), we should strive to understand the tools that can improve industries, by educating and learning, rather than relegating or restricting their use to niche roles. A good example of misunderstanding and misusing multiple software would be if you were working within a Microsoft Excel spreadsheet and printed off part of it to a PDF or physical copy. A coworker/manager decides to use this data (I.e. a table or graph, etc.) in a Microsoft Word document for a report, but uses a screenshot or scan of the data, instead of tracking down the spreadsheet and creating a data link that dynamically updates as the data changes. Using static data may not seem problematic, but without timestamps or a data trail, validating the authenticity of the screenshot or scan becomes a concern for data integrity. As the working world becomes more complex in how data is represented and interconnected, we must also keep up with the methodologies and processes that come with it. In short, how we treat a single tool, such as CADD software, is reflective of how we treat an entire design process for an industry. If the saying that “we are only as strong as our weakest link” is true, then it is on the technical users of any software and the beneficiaries to bridge the gap of knowledge to breed a successful process. Transparency, easier access to information, and availability to knowledgeable educators will provide engineering solutions that feel less supernatural and more in-touch with the world.